FRB Bearings providing:Cross roller bearing,YRT rotary bearing,Slew drive,Thin wall bearing,Slewing ring bearing,Roller & Ball bearing www.frb-bearings.com

Tuesday, July 31, 2018

3 Reasons-Why crossed roller bearing is the most suitable for robot arm?

The stretching and lateral movement of the robot arm all belong to linear motion. There are many kinds of mechanism to realize the reciprocating and linear motion of arm, such as piston oil (gas) cylinder, gear rack mechanism, screw nut mechanism and connecting rod mechanism. Because the piston oil (gas) cylinder is small in size and light in weight, it is widely used in the robot arm structure.

There are many kinds of mechanisms to realize the rotary motion of robot arm, such as vane rotary cylinder, gear drive mechanism, sprocket drive mechanism, piston cylinder and connecting rod mechanism. The most suitable bearing for robot arm is cross roller bearing. Why do you say that?

What kind of bearing cannot be reused and must be replaced?

Bearing is an important part of modern machinery equipment.Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotary precision.

How to determine whether the bearing can be used again and whether the bearing needs to be replaced: judge whether the bearing can be used again, judge whether the bearing can be used again?According to the damage level, mechanical performance, importance, operating conditions, inspection period and other related factors to determine.However, if the following defects are found during inspection, the bearing cannot continue to be used and new bearings need to be replaced.FRB BEARINGS make the following analysis.

Monday, July 30, 2018

How to determine the replacement time of slewing bearings?

To determine the replacement time of the slewing bearings, it is most convenient and reliable to use the iron spectrometer or SPM or HD-1 bearing working condition monitoring instrument to determine the working state of the bearing and determine when the bearing should be reported for repair.

Wednesday, July 25, 2018

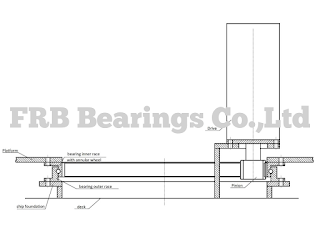

How to select the Marine crane slewing bearing?

Deck machinery is the special machinery equipment for ship outfitting, mainly including the anchor winch and ship crane installed on deck. Among them, the ship crane is mainly equipped with a series of characteristics, such as compact structure, convenient operation, large lifting weight, quick action, high efficiency and convenient maintenance, etc., in a large bulk cargo ship of 30,000-50,000-ton class, and plays an important role in modern ship deck machinery.

At present, the Marine crane has formed a series of production in China through the introduction and transformation of foreign technology in the past 20 years. Except the ordinary crane, the slimming crane, the double crane and the hose crane have also been produced in series. However, most ship cranes were imported from abroad before 2003, especially the slewing bearing in the rotary mechanism which connected the rotating tower body and fixed base column. As an extremely large ship crane kit, due to the particularity of the use environment, the selection and development design of the ship crane were still blank in China at that time. FRB Bearings work with a domestic Marine machinery factory to select and design slewing bearings.

Common faults and troubleshooting of mobile cranes slewing bearings

Mechanical failure

Crane slewing bearing plays the role of connecting the truck and chassis parts in the rotary mechanism, and also supports the whole rotating part of crane.If the steel ball in the swing bearings is damaged and the raceway abrasion will affect the work of the rotary mechanism, in severe cases, the rotary mechanism will be heavy and make noises, and the pressure of the rotary hydraulic system will exceed the rated value.When hoisting and unloading are carried out at the stop of rotation, the vibration amount of the slewing bearings will be too large at the moment of falling and falling together, indicating that the clearance amount of the slewing ring has seriously exceeded the limit.At this point, the turntable bearings should be repaired or replaced.

The general causes of mechanical failure are inadequate maintenance and improper use.

Monday, July 23, 2018

Repair and maintenance of excavator parts in summer

The summer is coming,how to repair and maintenance of excavator parts?FRB Bearing will be analyzed from the following points:

1.What are the aspects of daily maintenance of excavators?

All yellow nozzles and slewing bearings shall be covered with butter once every 10 days and 15 days, and butter shall be beaten twice every 4-8 hours at different angles. Each reducer shall be replaced within 520 hours after the first operation, and 2-3 times in the following year. The engine must be preheated for 10-15 minutes before operation.

What are the methods to prevent quenching crack of slewing bearings?

Cracks sometimes occur in the slewing bearing during quenching or at room temperature after quenching.Also called quenching crack of slewing ring.There are many reasons for quenching cracking of swing bearing. When analyzing quenching crack, it should be distinguished according to the crack characteristics of slewing bearing.Today, small editor to give you a key introduction to prevent swing bearing quenching crack methods.Let's study together!

1. Proper design of slewing bearing products - the design should be based on the working conditions, service requirements and reasonable design of the section size of swing bearing, correct selection of materials, in the structural design, as far as possible to meet the requirements of heat treatment technology on the slewing ring structure;

Thursday, July 19, 2018

Six tips-How to choose the suitable cross roller bearing?

Cross roller bearing is more and more widely used in recent years, but how to choose the most suitable model and structure, most customers who use cross roller bearings are confused by the problem, today FRB BEARINGS will explain how to choose the suitable bearing!

First cross roller bearing model is very, very much, which can be roughly divided into the following series: INA SX series cross roller bearing , THK RB series cross roller bearings, INA XSU series crossed roller bearing , THK RA series cross roller bearing , THK RE seriescross roller bearing RE, THK RU series cross roller bearings, IKO CRB series cross roller bearing and so on.

Wednesday, July 18, 2018

Do you know what the new type of wind turbine bearings?

The yaw bearing is installed at the joint between the tower frame and the cockpit, and the variable propeller bearing is installed at the root of each blade and the hub.Each wind turbine is equipped with one set of yaw bearings and three sets of variable rotor bearings (some wind turbines below the megawatt class are non-adjustable blades and do not need variable rotor bearings).

1. Identification code

Wind turbine yaw, variable propeller bearing code method is adopted in the JB/T10471-2004 slewing bearing code method, but the wind turbine yaw, variable propeller in the double row four-point contact ball slewing ring, and the code of the structure bearing no provisions in JB/T10471-2004, as a result, the increase in this standard the double row four-point contact ball bearings.Due to the structure of single row four-point contact ball slewing bearings with 01 type, according to the structure of code 02 said is double row reducer ball wheel bearing structure, thus provides 03 said double row four-point contact ball slewing bearing structure.

5 Points replace and disassemble the slewing bearing of excavator

The importance of the slewing ring of excavator in machinery is unspeakable.In addition, the slewing bearing is indispensable in excavator and is prone to various faults. For a period of time, new bearings should be replaced.Therefore, today FRB Bearings said that 5 Points replace and disassemble the slewing bearing of excavator.

5 Points replace and disassemble the slewing bearing of excavator:

Tuesday, July 17, 2018

3 tips: How to judge there are safety hazards in bearing operation by watching and listening?

Bearing is an indispensable part in the mechanical industry, and the quality of bearing affects the operation performance of machinery.We usually is removed bearing for testing, Today FRB BEARINGS teach you new skills: How to judge there are safety hazards in bearing operation by watching and listening?

Observation: should open the bearing box on a regular basis, in order to visual check bearing and oil seal, check of the condition of the near the bearing oil seal to ensure that they are enough to prevent hot liquids or corrosive liquid, gas along the axis of seeping into the bearings.

Monday, July 16, 2018

How to store the slewing bearing is not used for a long time?

Many manufacturers will buy a lot of swing bearings at one time to ensure adequate inventory of the warehouse, but the slewing ring will not be used for a long time, rust will occur, resulting in the slewing bearing can not be used normally. Today, we will explain how to store the slewing bearing that is not used for a long time.

Long-term storage conditions and items of slewing bearing:

1.The warehouse temperature: slewing bearing are coated with anti-rust oil before they go out, the temperature too low or too high will lead to rust-proof oil metamorphism, room temperature should be controlled in 0 to 25 ℃;

Wednesday, July 11, 2018

FRB Bearings Slewing bearing application fields

The slewing bearing has to be adopted when,in a machinery or in mechanical plant,a structural part must rotate opposed to another part,along a fixed axis,ensuring the axial and radial link between the two parts.The slewing bearing,with the maximum stiffness offered by its design,must bear and transmit the operative loads of the structure it is linked to,and also it must guarantee the required motion precision,the respect of operational parameters,and the required lifetime.

It is evident how the slewing bearing is a fundamental component and its choice must be done according to specific technical studies.FRB Bearings technical staff can assist your company in the choice of the suitable bearing.

Common application are:

excavators

concrete pumps

boomlift,manlift

crane truck

civil and harbour crane

compactors

wind turbines

radar

manipulators

filling carousels

rotary tables

demolitions shears

wrapping machines

forest machines

excavators

concrete pumps

boomlift,manlift

crane truck

civil and harbour crane

compactors

wind turbines

radar

manipulators

filling carousels

rotary tables

demolitions shears

wrapping machines

forest machines

Tuesday, July 3, 2018

YRT rotary table bearings load accuracy

YRT rotary table bearings is a kind of high precision bearing which is commonly used.At the same time it is widely used in medical machinery, CNC machine tools and even precision radar and other high precision equipment.So, must be every moment keep rotary table bearings a good condition and use of performance, need to maintenance, repair, in order to prevent accident arrangement, to ensure reliability of the turntable bearings, improve productivity and economy.Maintain it is best to check regularly, FRB BEARINGS introduces some matters needing attention for the general customers.

The inspection of YRT rotary table bearings includes monitoring operation condition, adding or replacing lubricant, and regular disassembly inspection.As an overhaul in operation, there are YRT rotary table bearings rotation sound, vibration, temperature, grease status and so on.When removing the bearing for maintenance, first record the appearance of the bearing, confirm the residual amount of lubricant, after sampling the lubricant used for inspection, clean the bearing.

FRB BEARINGS specializing in crossed tapered roller bearing

Cross roller bearings mainly has two kinds, one kind is crossed cylindrical roller bearing, and another kind is crossed tapered roller bearings, both are rolling on the v-shaped grooves perpendicular, the only difference is crossed tapered roller ring V groove according to the tapered roller Angle is different and different, so that the bearing capacity of larger, higher speed.

The design of cross taper roller bearings (XR/JXR series) can provide high rotation accuracy and rigidity in a small space, which can greatly save material cost.This type of bearing is the two sets of bearing raceway and roller according to the rectangular cross installed together, adjacent roller in the opposite direction, install a isolation block between roller and roller, the roller is also equipped with support gasket, this makes the roller of two and a half into the same space.The angular and conical geometry of the bearing makes the effective span of the bearing several times larger than the actual width of the bearing itself.

Monday, July 2, 2018

FRB Bearings Slewing ring bearings application

Every industry has its unique challenges, but virtually all industries share the goals of increased machine uptime, reduced maintenance, improved safety, energy savings and lower Total Cost of Ownership. With expertise in a wide range of disciplines and decades of experience as a technical partner to both equipment manufacturers and end users in every major industry, FRB Bearings is delivering not just products but total integrated solutions that help our customers achieve their goals.

Close cooperation with equipment manufacturers and industrial end users has given FRB Bearings a unique understanding of the interaction between asset components and industrial processes. Today, we are leveraging this knowledge to provide value at every stage of an asset’s life cycle. FRB Bearings Life Cycle Management is our proven approach to optimizing equipment design and operation over its entire service life cycle. Proven effective in our own factories worldwide, FRB Bearings solutions are also proving valuable to FRB Bearings customers worldwide.

Subscribe to:

Posts (Atom)

YRTS200 Rotary Table Bearing

Product Model: YRTS200 d:200mm D:300mm H:45mm weight:9.7kg YRTS200 bearing consists of thrust/radial housing washer,a thrust/radial...

-

FRB BEARINGS was founded in 2009, is one specialized is engaged in the large and super large slewing bearings and non-standard bearing de...

-

How to maintain the tower crane slewing ring? Here are 9 points for reference (1) Tower crane maintenance technology slewing bearing in...

-

Recently, many industries have released "2018 top technology forecast." The technologies that will play an important role in t...