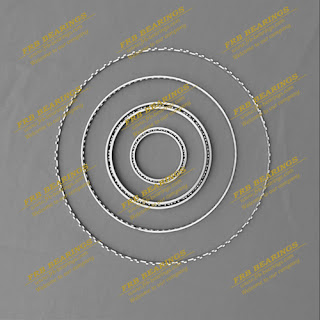

FRB Bearings providing:Cross roller bearing,YRT rotary bearing,Slew drive,Thin wall bearing,Slewing ring bearing,Roller & Ball bearing www.frb-bearings.com

Thursday, January 10, 2019

Incorrect bearing selection is the key to rapid damage

"All types of bearings have different characteristics due to their different designs.Due to the variability and complexity of the specific installation site and application of the bearing, there is no fixed mode for the selection of bearing type. When selecting the bearing type to adapt to the specific installation site and application conditions of a host, it is suggested to take the following major factors into consideration.

Allow space

Mechanical design, the general first determine the shaft size, and then choose the bearing according to the shaft size.Usually, the small shaft choose ball bearing;Cylindrical roller bearings, adjustable roller bearings, tapered roller bearings (sometimes also optional ball bearings).If the radial space of the mounting part of the bearing is limited, the bearing with a small height of the radial section should be adopted.For example, needle roller bearings, some series of deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings or self-aligning roller bearings and thin-wall bearings.If the axial space of the mounting part of the bearing is limited, the bearing with smaller width size can be used.

Bearing load

Load size load size is usually the determining factor in choosing the bearing size.The bearing capacity of roller bearing is larger than that of ball bearing with the same dimension.Usually ball bearings are suitable for light or medium loads, roller bearings are suitable for bearing heavy loads.

Load mode pure radial load can choose deep groove ball bearing, cylindrical roller bearing.Thrust ball bearing and thrust cylindrical roller bearing can be used for pure axial load.Radial load and axial load (combined load), the general choice of angular contact ball bearings or tapered roller bearings.If the radial load is large and the axial load is small, the bearing person WeChat professional!Deep groove ball bearings and cylindrical roller bearings with internal and external rings are optional.If at the same time there are shaft or shell deformation and installation of the neutral poor situation, you can choose adjustable ball bearings, adjustable roller bearings.If the axial load is large and the radial load is small, the thrust angular contact ball bearing can be selected. If the four-point contact ball bearing also requires the performance of centering, the thrust centering roller bearing can be selected.

Speed

The working speed of rolling bearing mainly depends on its allowable operating temperature.Bearings with low friction resistance and less internal heat are suitable for high-speed operation.When only bearing radial load, deep groove ball bearing and cylindrical roller bearing can achieve a higher speed. If bearing combined load, angular contact ball bearing should be selected.Specially designed high precision angular contact ball bearing can achieve extremely high speed.The rotational speed of all kinds of thrust bearings is lower than that of radial bearings.

Rotation accuracy

For the majority of machinery, choose a level 0 tolerance is enough to meet the host requirements, but on the axis of rotation accuracy have strict requirements, such as spindle, precision machinery and instrument etc., should choose high tolerance grade of deep groove ball bearings, angular contact ball bearings, tapered roller bearings, cylindrical roller bearings and thrust angular contact ball bearings.

Rigid

The rolling bearing rigidity is determined by the elastic deformation when it bears the load. In general, this deformation is very small and can be ignored. However, in some machines, such as machine tool spindle system, the static stiffness and dynamic stiffness of bearing have a great impact on the characteristics of the system.Bearing person WeChat professional!Generally speaking, roller bearings have higher stiffness than ball bearings.Various kinds of bearings can also improve their rigidity to varying degrees through proper "pretightening".

Noise and vibration

The bearing noise and vibration are generally very low.However, for small and medium-sized motor, office machinery, household appliances and instruments on the noise and running stability of the machinery has special requirements, usually choose low noise bearings.

Axial moving

The most common arrangement of bearings is to install a set of axially positioned "stationary bearings" at one end of the shaft and a set of axially movable "moving bearings" at the other end to prevent the shaft from sticking due to heat expansion and cold contraction.The "moving bearing" often used is the cylindrical roller bearing with inner ring or outer ring without flanging. At this time, the fit between inner ring and shaft or outer ring and shell hole can be interference fit.Sometimes it is also possible to choose non-detachable deep groove ball bearing or self-aligning roller bearing as swimming bearing, but the inner ring and shaft or outer ring and shell hole should be fitted with clearance to ensure that the inner ring or outer ring has enough freedom of axial movement.

Friction torque

The ball bearing friction resistance is smaller than that of roller bearing.When the pure axial load is applied, the friction resistance of the axial contact bearing is small.The friction resistance of angular contact bearing is the least when the bearing contact Angle is close to the load Angle.In the instruments and machines that need low friction torque, ball bearings or cylindrical roller bearings are more suitable.Bearing person WeChat professional!In addition, low friction torque bearings should avoid using contact seal, at the same time, it is recommended to use drip lubrication, oil and gas lubrication or other lubrication methods conducive to reducing wear.

Installation and removal

Bearings with cylindrical inner holes are used in machinery with frequent installation and disassembly. The priority should be given to angular contact ball bearings, tapered roller bearings, separable cylindrical roller bearings, needle roller bearings and thrust bearings.Bearings with conical bore can be mounted on the journal, or mounted on the cylindrical journal by means of a retaining sleeve or a dismounting set for easy installation and disassembly.

Subscribe to:

Post Comments (Atom)

YRTS200 Rotary Table Bearing

Product Model: YRTS200 d:200mm D:300mm H:45mm weight:9.7kg YRTS200 bearing consists of thrust/radial housing washer,a thrust/radial...

-

How to maintain the tower crane slewing ring? Here are 9 points for reference (1) Tower crane maintenance technology slewing bearing in...

-

FRB BEARINGS was founded in 2009, is one specialized is engaged in the large and super large slewing bearings and non-standard bearing de...

-

When designing and manufacturing rolling bearings, What's the selection principle of slewing bearing steel?The following principles ...

No comments:

Post a Comment